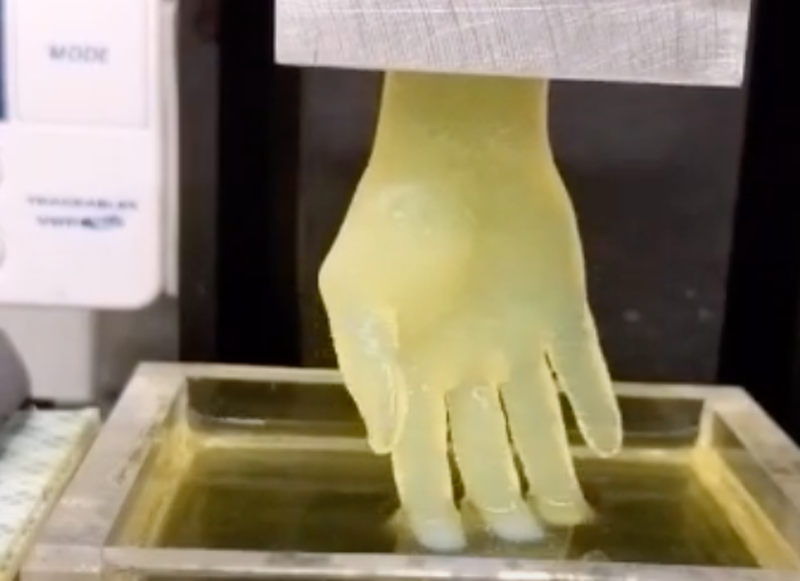

The high-speed 3D printer, developed by a research team at New York State University’s Buffalo campus, published in the academic journal Advanced Healthcare Materials (AHM), is fast enough to create an artificial prosthetic in 19 minutes. It would take 6 hours for a typical 3D printer to be processed at this speed.

The research team said that the technology developed this time is 10 to 50 times faster than the industry standard, and that it is possible to produce large-sized samples that were considered difficult so far. In addition, it is explained that this method can quickly create a centimeter-sized hydrogel model, and the problem of deformation or damage due to prolonged exposure to environmental stress seen in the existing method is greatly reduced.

What this high-speed 3D printer uses is a stereolithography method. The liquid resin and hydrogel are fixed with a laser. Hydrogels are already being used in many general products such as contact lenses and diapers, but it seems that there was a thought of using them for biomedical applications. According to the research team, a hydrogel is suitable for producing small cells surrounded by blood vessels with a 3D printer. In the future, vascular cells are tasked with making muscle tissues or organs with a 3D printer. Related information can be found here.