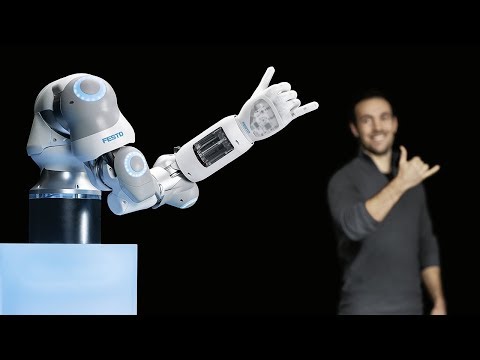

BionicSoftHand is a robotic hand developed by a German company, Festo, with soft fingers as human beings. The product learns through trial and error until artificial intelligence completes a given task.

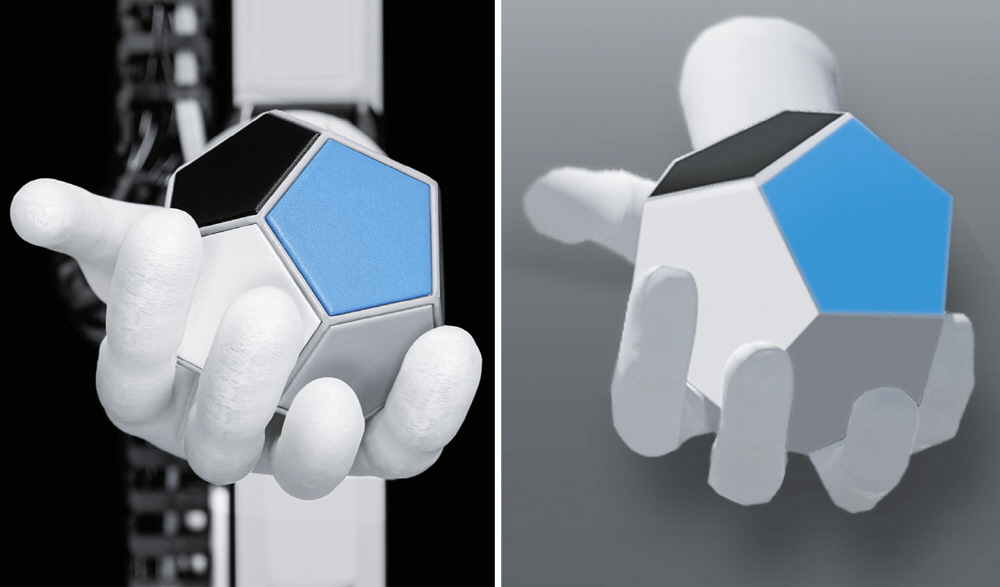

Bionic Soft Hand recognizes mouse objects in their hands and creates virtual copies of them through a 3D camera and depth sensor for the tasks to be handled. Artificial intelligence then goes through a series of simulations of virtual copies to find out what to do. When the answer is pulled out, the contents are transferred to the robot hand and the actual work is performed.

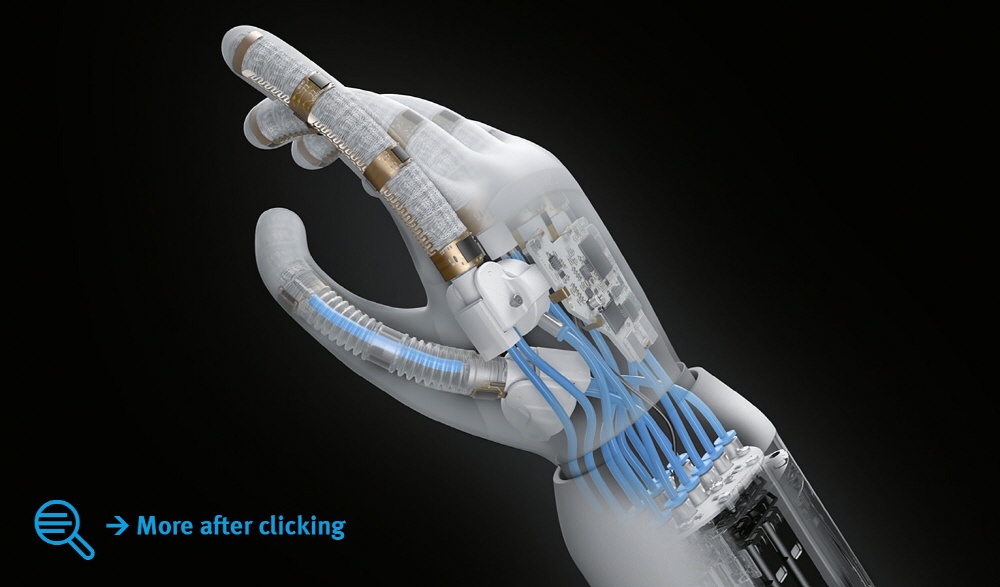

In the video, we can see how artificial intelligence learns how bionic soft hand rotates without giving up the dodecahedron. A flexible circuit board was combined with a finger tactile sensor to cover each finger with a high-strength fiber fabric with a corrugated structure moving joints with high-pressure air. The thumb has a rotation module that does not have the other fingers and can be given 12 degrees of freedom with every finger. This is to process the object through it.

Of course, it will take some time for the bionic soft hand to be used in production activities at factories. However, since the machine learning itself is characterized by an increase in learning ability in proportion to time, it is expected that when both the artificial intelligence and the hardware are developed, the robot hand will be able to perform various tasks more autonomously. For more information, please click here .