Recently, it is attempting to develop high-performance transistors using carbon nanotubes instead of transistors using conventional silicon. The MIT research team revealed that they succeeded in solving the problem related to transistors using carbon nanotubes and displaying the phrase (Hello World).

Electronic circuits and transistors, which are the basis of microprocessors mounted on computers, etc., are made of a combination of small semiconductor elements. As Moore’s Law, which says that the number of transistors doubles every two years, has reached its limit in the past few years, carbon nanotubes are drawing attention as a new transistor material to replace silicon.

Carbon nanotubes have high electrical conductivity, and CNFETs (Carbon nanotube field-effect transistors) are expected to achieve 10 times energy efficiency compared to silicon transistors. However, there are many challenges in transistors using carbon nanotubes, and it has been difficult to realize a microprocessor that can withstand practical use.

According to the research team, there are three challenges in building a carbon nanotube transistor. The first is that when carbon nanotubes are placed on a wafer, uneven amounts and excessive deposits are formed. Second, carbon nanotubes are divided into two types: semiconductor type and metal type. Third, it is difficult to make P-type and N-type semiconductors of transistors. The MIT research team devised a solution to overcome this problem.

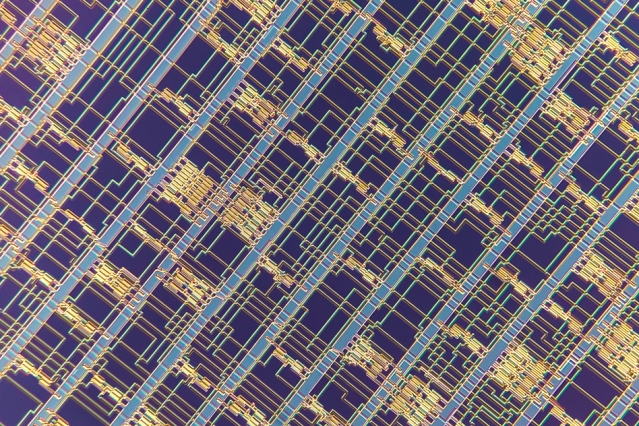

When making a transistor made of carbon nanotubes, the carbon nanotube solution is spread over the whole to burn the carbon nanotubes on a silicon wafer. At this time, most of the carbon nanotubes become uniform on the wafer, but sometimes it interferes with manufacturing large-scale transistors of 1,000 or more.

The research team was focused on the fact that the carbon nanotubes in contact with the wafer have a stronger binding force with van der Waals force than individual carbon nanotubes. Pre-processed. Through this, it is said that it has succeeded in exhaling only the areas that are excessively hardened between carbon nanotubes.

In addition, when manufacturing carbon nanotubes, it is mixed with most of semiconductor-type carbon nanotubes and produced as a small amount of metal-type carbon nanotube mixture. Carbon nanotubes used in transistors require semiconductor characteristics, but when metallic carbon nanotubes are mixed, transistor performance deteriorates or operation stops. To solve the problem, it is necessary to increase the purity of semiconductor-type carbon nanotubes to 99.999999%, but the purity of about 9.99% is limited with the current technology.

The research team developed a solution not to increase the purity of semiconductor-type carbon nanotubes, but to allow the presence of metallic carbon nanotubes. The reason that purity is important is that noise signals are generated in the processor logic circuit. Through simulation, the research team solved the problem of metal-type carbon nanotube mixing by identifying logic circuits that are susceptible to noise signals from metal-type carbon nanotubes and building a processor with a combination that avoids them.

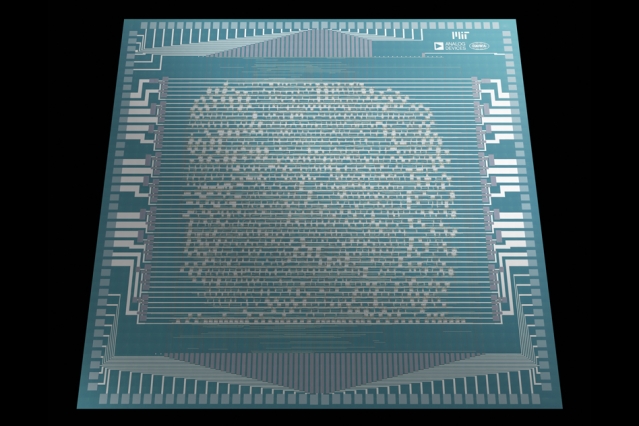

In addition, it has developed a technology to build a P-type semiconductor and an N-type semiconductor by attaching metal oxide to the carbon nanotube layer. In this way, the research team succeeded in constructing a 16-bit microprocessor named RV16X-NANO by making a transistor using carbon nanotubes as before.

The microprocessor developed by the research team used 14,000 transistors made of carbon nanotubes and was able to execute the RISC-V instruction set. In fact, the research team said that they were able to display new messages (Hello, World! I am RV16XNano, made from CNTs) through a program that displays classic phrases (Hello World).

The research team says that it is the most advanced chip made of new nanotechnology that is promising for high-performance, energy-efficient computers. Silicon has its limitations, and that carbon nanotubes will be one of the best ways to overcome these limitations. Related information can be found here .