Industrial robots are mechanical devices that perform assembly work. Most of the products you see around you are actually industrial robots in charge of some of the production. While industrial robots have developed remarkably in recent years, it is also true that there are companies that have not introduced industrial robots. It is pointed out that robots can take away human work, but a study found that the introduction of industrial robots increases the number of workers, improves performance, and increases productivity.

Since the advent of industrial robots, many studies have been published on the effects of industrial robots on the manufacturing industry. For example, industrial surveys in 17 countries over the past 14 years from 1993 to 2007 show that industrial robots contributed 15% of the total production rate of the economy.

However, most of these studies were conducted on the premise that all companies have introduced industrial robots at the same level. In this matter, a research team at Bayreuth University in Germany conducted an investigation to see what makes the difference between companies that have introduced industrial robots and those that do not.

The data on which the study was based was provided by ESEE, an annual survey of 1,900 national manufacturing industries conducted by Spain. According to the research team, Spain is also one of the countries with the highest ratio of industrial robots per worker in Europe. ESEE has determined that it is suitable for this study because it contains industrial robot usage data in each company’s production line.

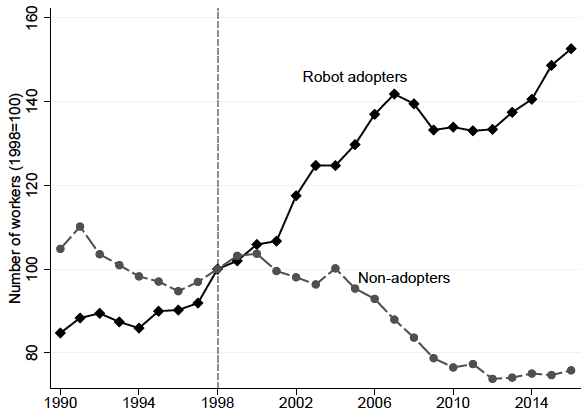

In ESEE data, when looking at the change in the number of workers by year for companies that have adopted industrial robots and those that do not, the number of employed companies has steadily increased since 1998, but on the contrary, the number of non-introducing companies has decreased since 1998.

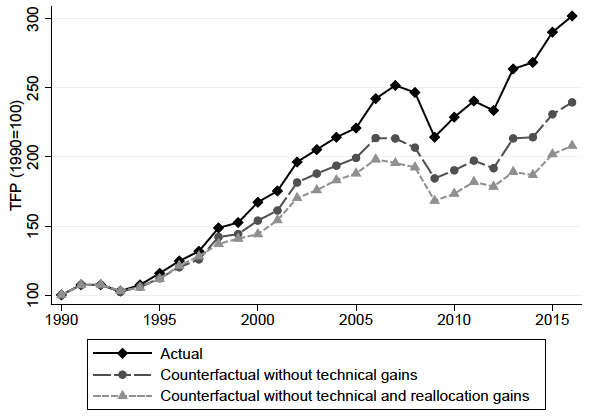

In addition, in the case of the difference in productivity of all factors that indicate technological development and production efficiency for the introduced and non-introduced companies, in this study, the total factor productivity was defined as direct and indirect efficiency improvement by the introduction of industrial robots. Direct efficiency improvement means how efficient the actual production line has been by industrial robots. Indirect efficiency improvement refers to efficiency improvement by shifting worker assignments due to the introduction of industrial robots.

From 1990 to 2015, even companies without industrial robots increased their productivity from 100 points to 200 points. However, the number of introduced companies increased from 100 points to 300 points, and the introduction of industrial robots nearly doubled the productivity of all elements. Among these, direct efficiency improvement was less than 70 points and indirect efficiency was less than 30 points. This means that the impact of industrial robots on the production site does not stop at simply improving production line efficiency.

According to the research team, companies that have introduced industrial robots show an increase in output from 20% to 25% within 5 years. Also, contrary to the general concern that robots will take away jobs, the introduction of industrial robots increased total employment by 10%.

The conclusion of this study reveals that companies that have introduced industrial robots have good performance and workers increase, while those that have not introduced industrial robots have reduced output and deteriorated the employment situation without opposing high-tech companies. Related information can be found here .

Add comment