There are a number of risk factors in space, which is completely different from Earth, such as the Moon and Mars advance plans. In the midst of this, a new technology for making skin and bones with a 3D printer was developed using human plasma as a material for skin transplantation or bone transplantation in a space where medical technology is limited.

The technology to immigrate to space, such as the Mars migration plan, is developing, but there are still many dangers for humans to live in space. It is also a problem that spaceships cannot take all the necessary medicines due to limited space. For example, you may be burned in space and need a skin graft, or a fracture may have caused a bone graft. In this case, what was devised as a solution is to make and implant skin and bones with a 3D printer.

If a part of the astronaut’s body is implanted due to burns or fractures, there is a possibility that the implantation site may not be treated in space, but 3D bioprinting can prevent such secondary damage. 3D bioprinting uses the astronaut’s own biomaterials such as plasma, so there is no rejection reaction.

It is for this reason that the research team at Dresden University Hospital and OHB System AG (OHB System AG), a developer of large-scale microgravity 3D printers for the purpose of mounting an international space station, released 3D bioprinted bone and skin samples.

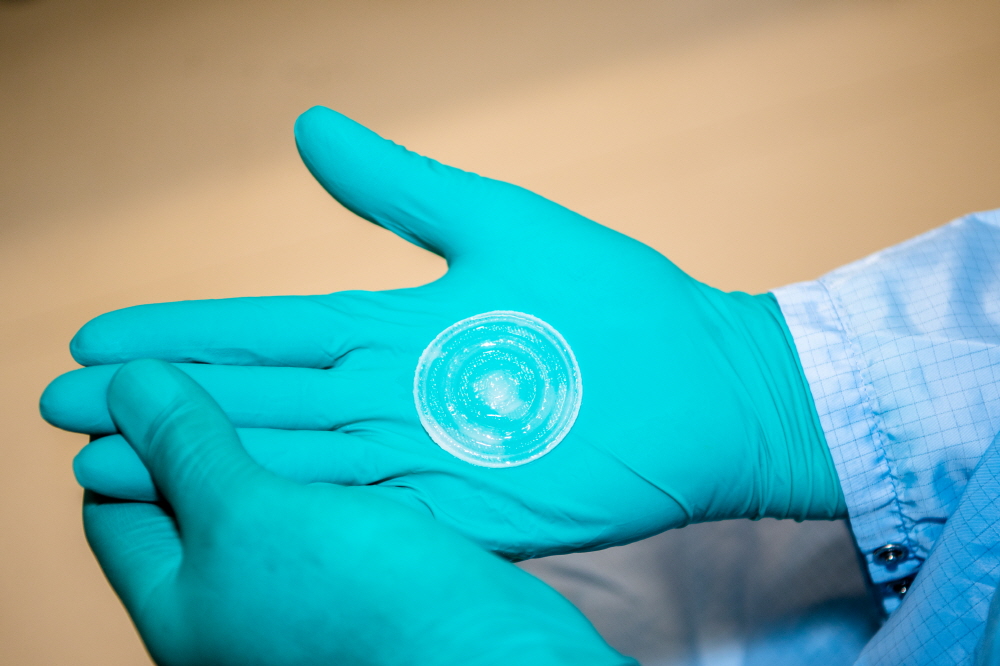

The research team uses human plasma as a nutrient-rich bio-ink for bio-printed skin cells. It can be obtained from the crew on the mission. Because plasma is a liquid, it doesn’t work well in environments where Earth and gravity are different, but the team added cellulose and alginic acid to it to increase its viscosity. In space where self-sufficiency is required, astronauts can obtain these materials from plants and algae.

Skin and bone samples were printed upside down to confirm whether bioprinting could be realized in the universe. It is said that next time, the experiment will be conducted over a long period of time even in a negative 1G environment.

Looking at the video, a real 3D bio printer is used to create thick skin by overlapping bio-ink. The bones also use transparent and white opaque materials as well as when printing skin. The opaque material is obtained by adding phosphoric acid to bio-ink to increase its strength. Since the skeleton requires strength, two types of bioink are used. Related information can be found here .

Add comment