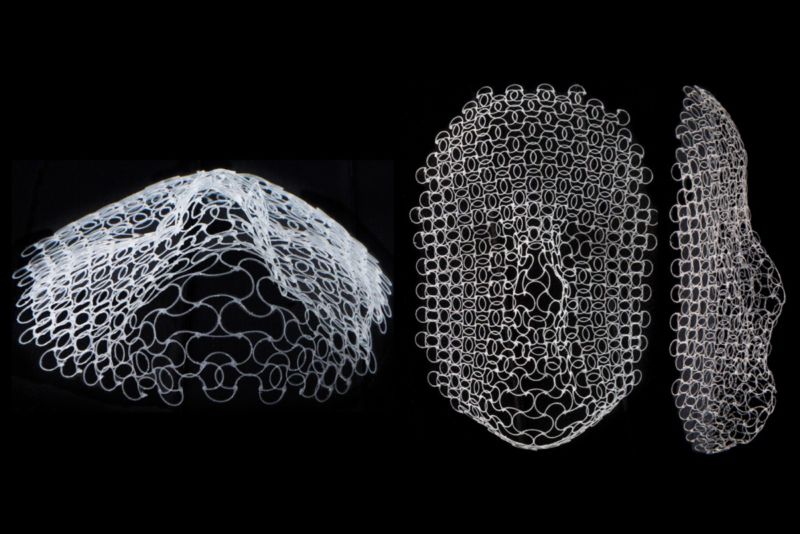

The MIT research team developed a special lattice structure that was originally flat and gradually changed into a shape like the contour of a human face as the ambient temperature changes.

The next technology next to 3D printing is the 4D printing material that attracts expectations. Like 3D printing, 4D printing prints material continuously and layer by layer under computer control, but the difference is that the printed material changes shape according to time and temperature. The MIT research team announced the achievements in the American Academy of Sciences Newsletter by creating a memory of a much more complex human face contour than has been made so far with 4D printing.

The MIT research team has succeeded in transforming a thin, flat plate into a shape such as a sphere, a dome, or the contours of a human face with changes in ambient temperature. Converting a flat plate into a human face contour is quite difficult to realize as it requires a material that can be enlarged or reduced beyond its original surface area. However, the research team came up with the idea of using a mesh-like lattice structure, and made the lattice structure from a rubber-like material that expands when the temperature rises, or transformed it into a human face contour in an airplane.

The research team also designed an algorithm that maps the figures necessary for the plane to change into the contours of a human face to a virtual map and converts the virtual map figures into planes, so that the mesh shape sheet can be expanded by different parts. The simulation succeeded in reproducing the flat sheet with temperature change. In addition, the mesh structure devised by the research team was cured by heating in an oven printed by an actual 3D printer, and then cooled to room temperature in salt water. We also confirmed that this sheet actually changes shape from a plane to a facial contour with a change in temperature.

The research team succeeded in creating a lattice structure containing conductive liquid metal and a shape change sheet that would change the shape of the frequency change. The use of the shape change sheet invented by the research team is expected to be applicable to tents that automatically expand, telescope lenses that can be deformed, artificial tissue scaffolds, and soft robots using soft materials. This material is used as an actuator such as a robot jellyfish or artificial muscle that changes its shape to swim when submerged in water.If this material is used, the shape of the actuator can change, providing a new design for soft robotics. Related information can be found here .

Add comment