The puzzle-like pattern of Nike Atsuma sneakers is more than a unique design. It is a trick to reduce waste from the shoe manufacturing process.

In general, sneakers are made by cutting leather or fabric material into pieces and then stitching them together. The pieces cut off in the process are piled up like garbage on the floor. Nike Atsuma can be seen as a product designed to minimize such waste.

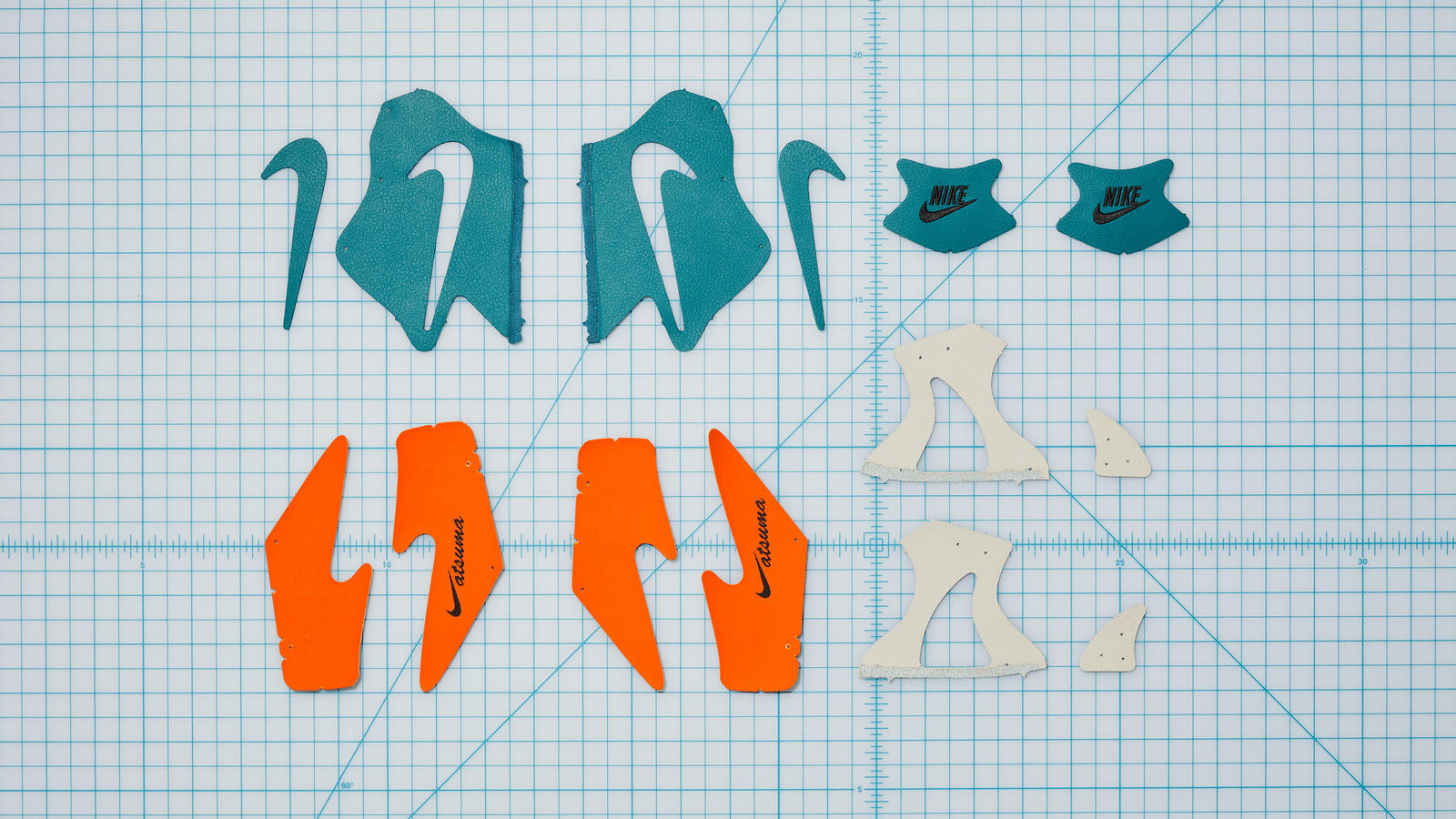

Here’s how Nike designed Atsuma without leaving any waste. Atsuma is designed symmetrically so that one part of the shoe can be designed and the remaining fabric can be used for the design of the other side. After being used in one design, the remaining pieces are used in the form of waves on the other side. The remaining pieces are also used as a heel counter that holds the ankle behind the shoe. The small cut pieces become eyestays that hold the shoelaces, and the design on the other side and the corresponding design is completed. In addition, the rubber sole is made and the remaining pieces are not thrown away and used again as a hang tag. As if putting together pieces of a puzzle, if you connect several pieces together, you will have a complete shape.

Nike is looking for a way to use all of the materials while maintaining its shape whenever it is cut. Designers involved in making Atsuma are said to have been inspired by fly knit, a knit technique used in shoe brands in 2012. The flyknit shoes developed by Nike are made by weaving seamless threads. Flyknit shoes with the feeling of being integrated with the feet like socks are made by weaving a single material seamlessly, so there is no need to cut and weave in the shoe process, so there is no remaining stock. According to Nike, the flyknit manufacturing process leaves 60% less waste than before. The Nike design team is contemplating how to remove waste from materials used in traditional shoes that are not made with flyknit technology.

Nike is looking for a way to use all of the materials while maintaining its shape whenever it is cut. The designers involved in making Atsuma were inspired by fly knit, a knit technique used in shoe brands in 2012. Flyknit shoes are made by weaving threads seamlessly. Flyknit, which feels like a sock, is united with the feet, is made by woven seamlessly from one material, so there is no need to cut and weave in the shoe process, so there is no remaining stock. According to Nike, the flyknit manufacturing process leaves 60% less waste than before. The Nike design team is now contemplating how to continually eliminate waste from materials used in traditional footwear.

Nike goes further and challenges zero waste by eliminating waste from the shoe manufacturing process. While wondering if this philosophy will change the type of shoes Nike will make, Nike is also trying to stick to the recycling design principle. The Playleather shoes, which were introduced in 2017, are made using discarded leather. A new fiber is made by collecting cowhide that is discarded in the process of making leather products. Fly leather products use 50% or more recycled materials. Nike has also run a Reuse As shoe program that collects and recycles old shoes regardless of the brand, and has also unveiled shoes made of ground materials made of pieces from recycled shoes.

Add comment