The University of Queensland research team announced that it has succeeded in developing a new biodegradable mask material that is inexpensive and can be mass produced. It is said that a mask made of this material can block viruses below 100 nanometers and has high breathability, making it suitable for long-term wear.

Masks like N95, which can block the Corona 19 virus, have difficulty breathing, so they are not suitable for long-term use or for use by the general public during daily life. In addition, it is pointed out that the manufacture of the N95 mask requires an ultra-fine fiber non-woven fabric made by a method called kuraflex, but the equipment for making non-woven fabrics is expensive, so it takes half a year to manufacture the machine.

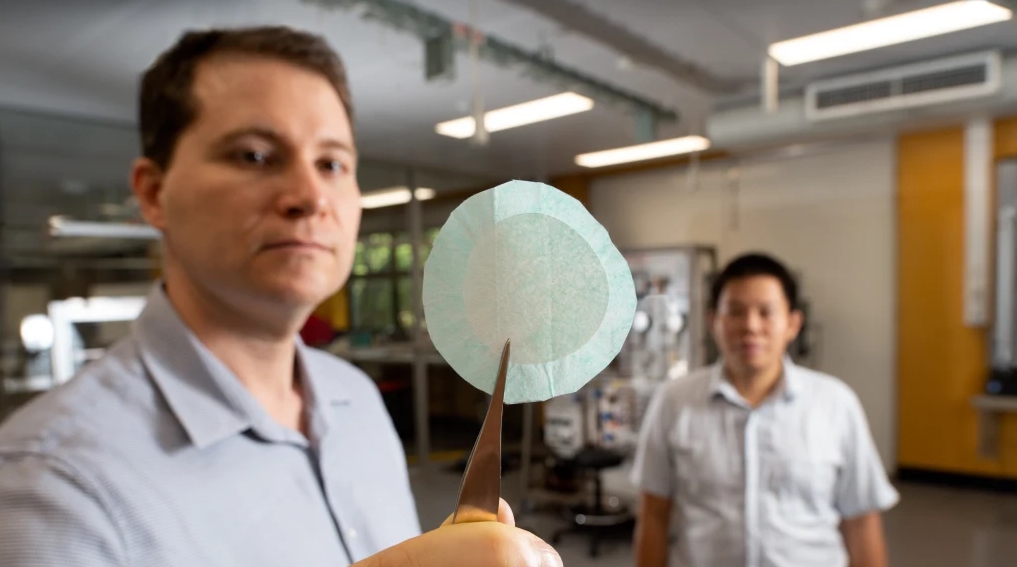

Meanwhile, the University of Queensland research team succeeded in developing a new material for masks that can be mass-produced inexpensively and quickly. As a result of testing the particle trapping performance using this material, it is said that particles of less than 100 nanometers, which are the size of a common virus, could be removed. In addition, it is said to be suitable for long-term wear as it has higher breathability than those on sale.

The researchers tested the material and found that its performance and efficiency in removing virus-sized nanoparticles was higher than that of a comparable commercial mask. The research team started developing materials in 2014, and it was originally supposed to use a disposable filter to purify diesel engine exhaust gas. However, as research entered 2017, it was discovered that the material under development is suitable for masks and personal protective equipment.

At first, it was considered to use a dust mask for firefighters, but it is said that the material’s ability to filter fine particles in the process of development was optimal for medical masks, so it took more time to complete this material.

This material is made of cellulose nanofibers made from sugar cane left over after squeezing sugar from sugar cane. It is explained that it is biodegradable because it uses vegetable wastes such as agricultural waste as raw materials, and can be mass-produced in a short period with relatively simple equipment, making it suitable for disposable cartridges for mask filters.

The research team explained that it has succeeded in proving the concept with this new nanoparticle filtration material, and that it is recruiting industry partners for practical use. Related information can be found here .

Add comment