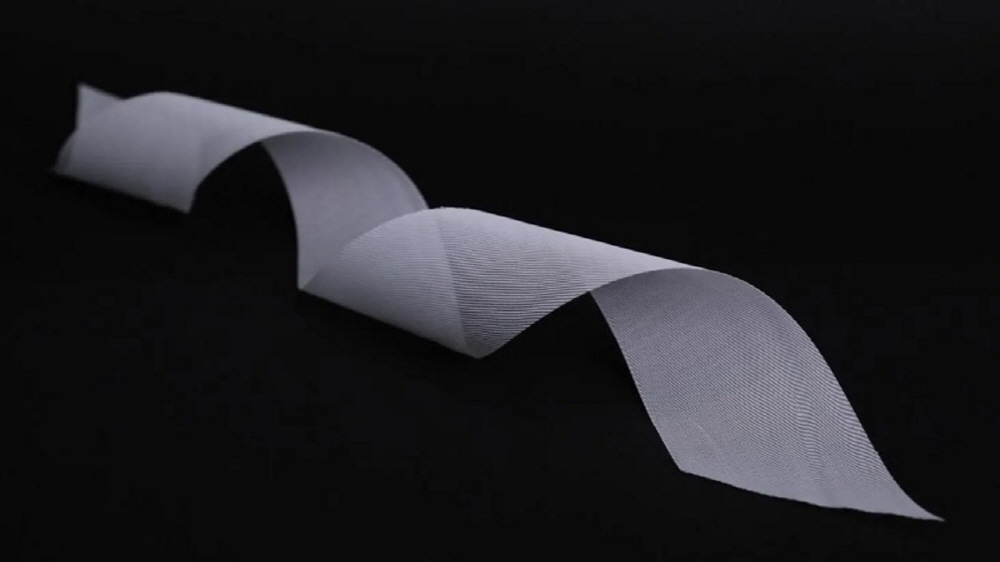

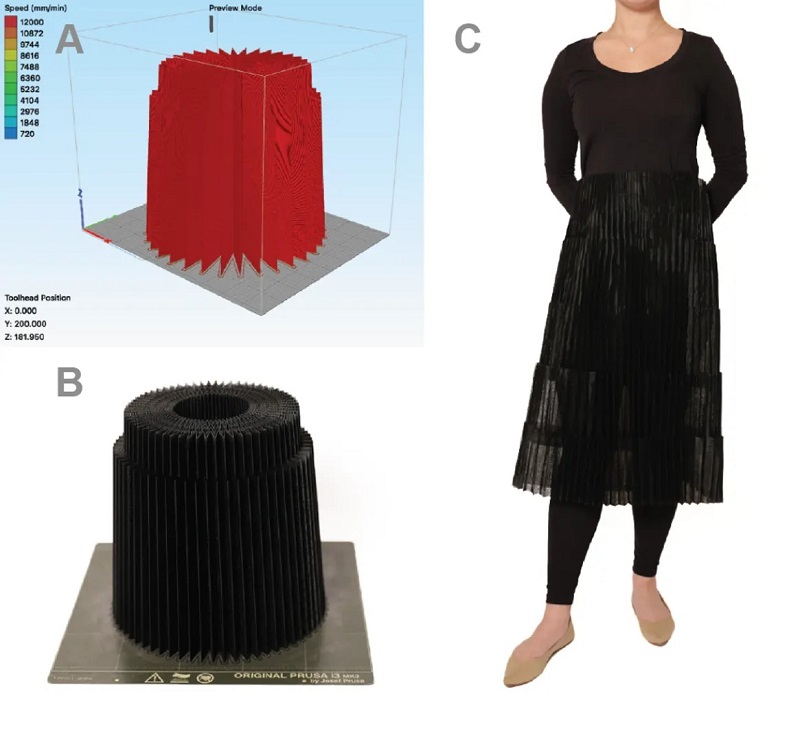

DefeXtiles was made by Jack Forman, a graduate student at MIT Media Lab, and is a semi-fabric using imperfect sculptures for clothes. It allows you to create a wrinkled skirt that can be worn by connecting it to a general 3D printer and sculpting it with parts. It is a home 3D printer that mimics irregular spurts and makes light and flexible laces out of hot plastic.

Depec Style is made by making a fabric by repeating a sufficient number of times while the print head extrudes resin and moves at regular intervals. Because the thread is flexible, it can be shrunk like a conventional fabric. The research team explains that, unlike previous studies, this study does not require custom software and hardware, and is the most common type of low-cost $250 3D printer that can be used by millions of people.

The research team succeeded in printing with flowers and other decorations. Of course, the real goal is to use these fabrics in the medical field. It is explained that Depexstyle can be used to produce effective customized surgical mesh at an affordable price that reinforces organs and tissues after surgery. Surgical implants made with 3D printers are already producing promising results through research. In addition, it contains antibiotics such as ciprofloxacin hydrochloride, which slowly releases antibiotics as they break down, helping to prevent infection. Related information can be found here .

Add comment