RightHand Robotics is a company that develops robotic arms to replace warehouse workers who will be responsible for delivering online shopping products. Robots are already used in many industrial fields, but it was technically impossible to use robots for handling e-commerce related products such as internet shopping malls. However, the demand for online shopping is increasing due to the corona 19 effect. In fact, while online shopping annual sales are growing by 20%, there is a problem that the number of people working in the field is decreasing.

The task that robots have been difficult to do is a simple and repetitive task of picking up products to deliver goods purchased in online shopping. In a typical warehouse, this task of grabbing a product is repeated ten times until product dispatch.

Light Hand Robotics has found a business opportunity here. However, even if it is a simple task of holding a product, there are millions of product types that can be purchased online, and since we do not know which product will be ready for shipment, if we have a robot instead of a human to grab the product, the robot will be a product that we have never seen before. It should be able to catch, including.

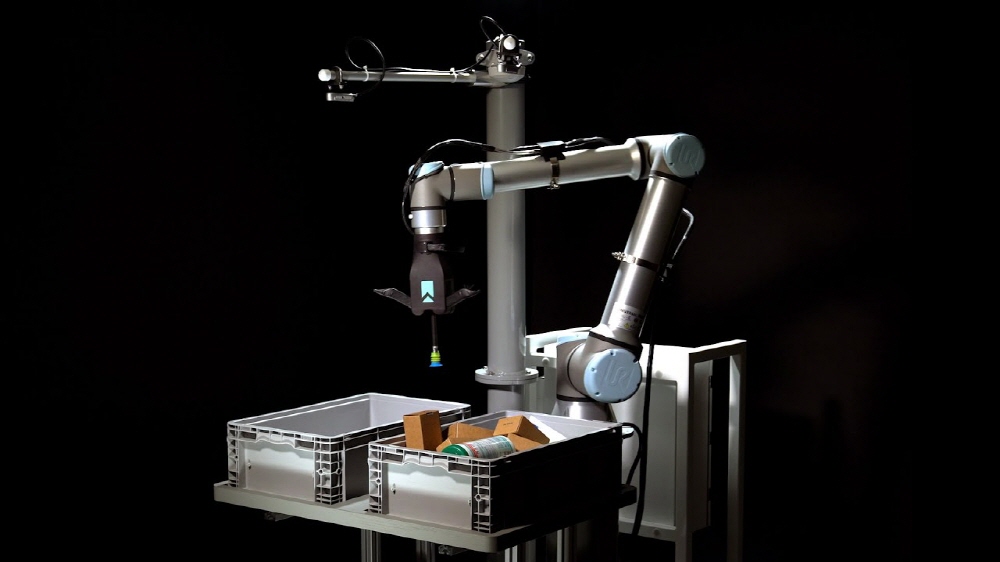

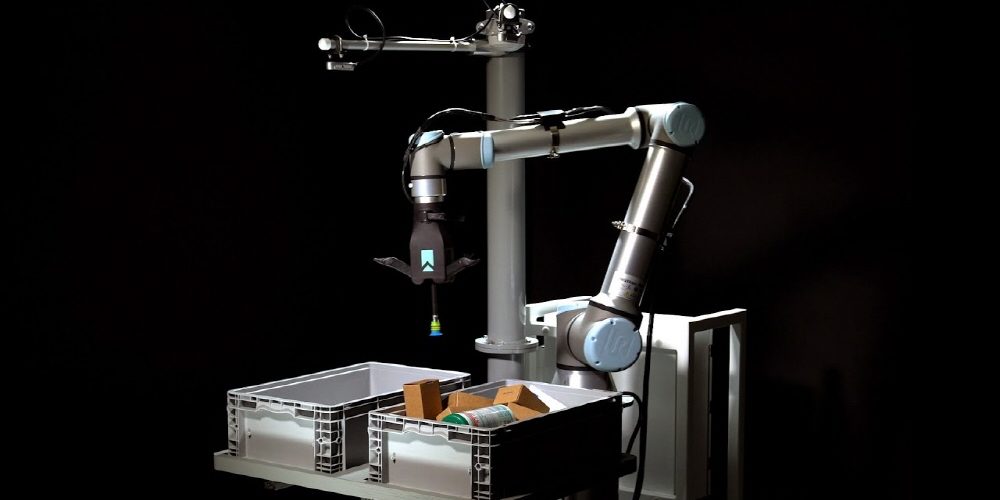

Light Hand Robotics had to develop a robot with intelligence and technology that supports 3Rs (Rate, Reliability, Range) of high efficiency, high reliability, and vast range. A team of robotics, computer vision, machine learning experts, software developers, hardware designers, and warehouse work experts who actually performed shipping work, and developed RightPick, a terminal that integrates 3D computer vision and smart gripper software. did.

In fact, Lightpick conducts product classification. First, the inventory product is recognized as a visual device and a color image with depth information added is output. The image is analyzed with a segmentation algorithm to select the product to be captured. The smart gripper for grabbing goods has been patented. The tip of the gripper is equipped with a suction device, and it is said that it is possible to take out small products with pinpoints in a narrow space. Holding a small product as if absorbing it with the force of inhaling air. Since the picked up product is held by the finger part smoothly, it holds the product in various shapes softly and safely.

Then, it checks whether the image recognition function holds the product correctly. Since LightPick is connected to the cloud, the task of holding a product is automatically converted into data and transmitted to the neural network. Based on this data, performance can be gradually improved.

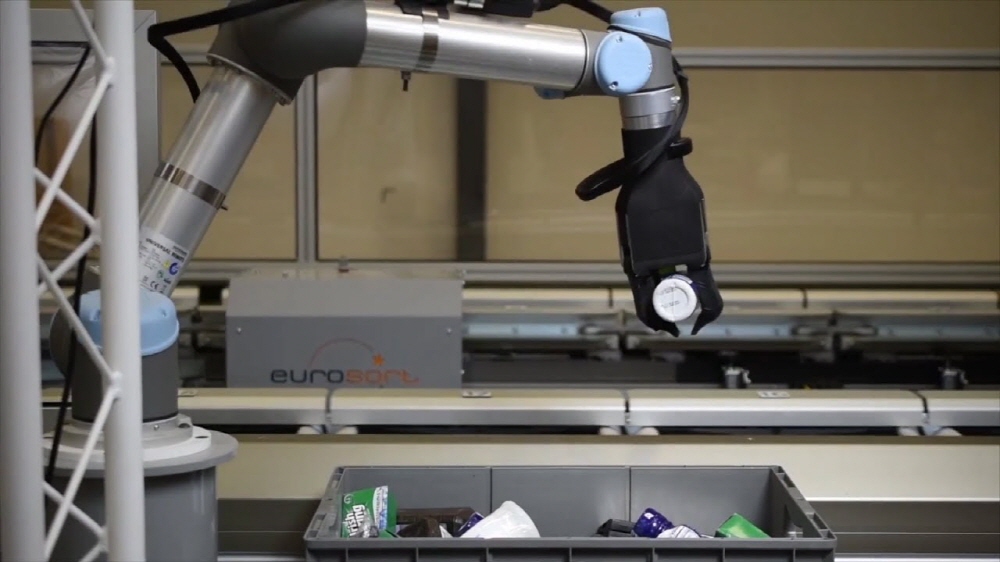

Lightpick is already active in warehouses where worldwide shipments are carried out. It is also possible to drastically reduce labor costs by introducing multiple units. The company has already announced the next model, RightPick2. Related information can be found here .

Add comment