As a result of the corona 19 infection epidemic, 690 million disposable masks are discarded every day worldwide, which is developing into a serious garbage problem. A research result was announced that it could be recycled without reclaiming a large amount of resources by using a disposable mask and dismantled building debris as road materials.

The use of PPE, a personal protective equipment represented by disposable masks, is also rapidly increasing due to the corona 19 effect. It is also reported that 129 billion disposable masks and 65 billion gloves are being disposed of worldwide every month. The data on which this calculation was based also included the period before governments mandated wearing masks. As a result of a recalculation by a researcher at the Australian Royal Melbourne University, the number of disposable masks used around the world reached 6.87 billion per day, and weighed 206,470 tons.

Discarded PPE is highly likely to be contaminated with Corona 19, making it difficult to handle, and because it is not a biodegradable plastic, it cannot be naturally decomposed and returned to soil. Therefore, it is common for discarded disposable masks to be incinerated or sent to landfill.

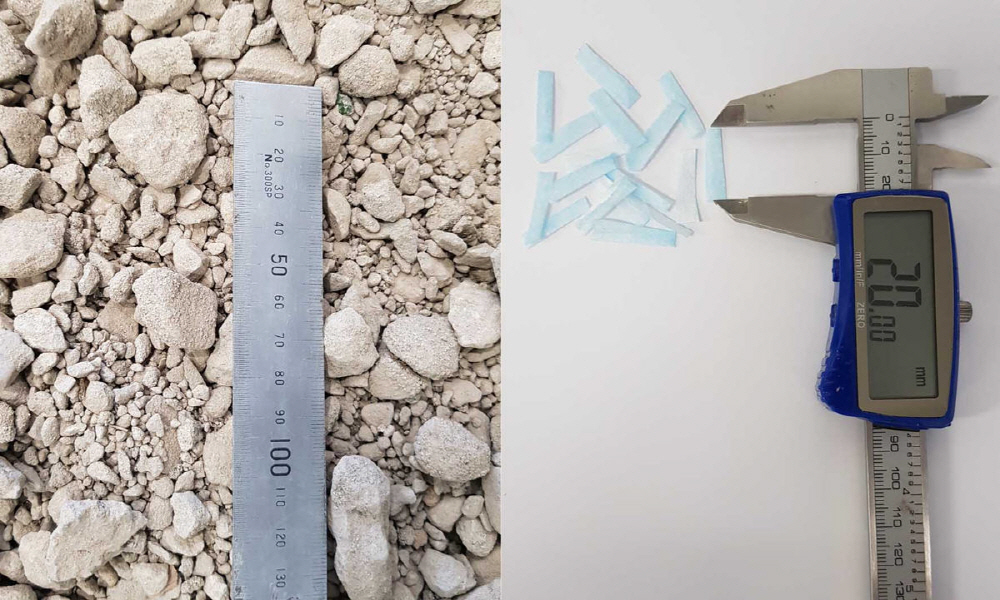

Therefore, the research team conducted an experiment to investigate the aptitude as a road pavement material by mixing disposable masks carved into recycled concrete aggregate (RCA). RCA is a building material made of concrete fragments, etc., generated when a building is dismantled. It is known that about half of the waste generated every year in the world is related to building construction, repair, and demolition, and in Australia alone, 3.15 million tons of RCA are left unused annually.

It is said that the packaging material made by mixing RCA and disposable masks in a weight ratio of 99:1 shows excellent results in tests such as stress and acid resistance, water resistance, strength, deformation and dynamic properties, and satisfies all the requirements for the use of packaging materials.

If the used disposable mask is reused, virus contamination is a concern, but the research team said that it is possible to kill 99.9% of the Coronna 19 virus by spraying a disinfectant solution on the disposable mask and heating it in an 800W microwave oven in general households. In addition, in the case of using a packaging material made of a disposable mask, it is also considered that the packaging material is left outdoors for a week to inactivate the virus in order to avoid the risk of infection.

The research team added that the polypropylene layer used in the disposable mask increases the strength of the packaging material. Considering that most of the PPE is made of polypropylene or polyvinyl chloride, PPE can also be used as a packaging material in addition to the disposable mask. According to the research team’s estimate, 3 million masks can be reused with only 1km of pavement on a two-lane road from packaging including disposable masks, and landfill waste will also be reduced by 93 tons.

The research team explained that if the packaging material is made with a disposable mask, there is no problem with the road material, but rather, it has an engineering advantage. It is explained that adding the concept of a circular economy to the waste problem caused by Corona 19 may also find a smart and sustainable solution. Related information can be found here.

Add comment