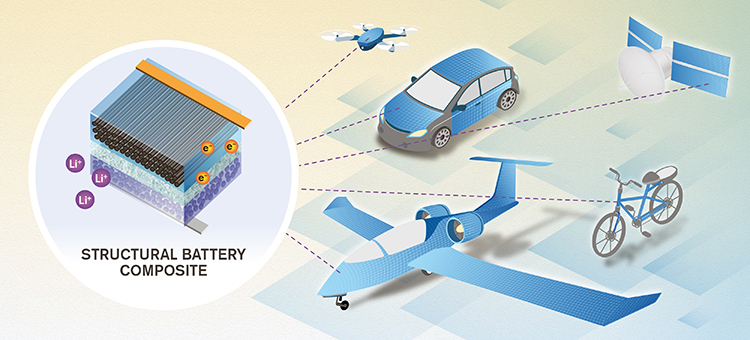

Since the battery installed in an electric vehicle is heavier than a normal gasoline engine, the body of an electric vehicle is heavier than a gasoline vehicle in the same class, and the weight of the battery is an obstacle to improving the fuel efficiency of an electric vehicle. Professor Leif Asp of Sweden’s Chammers Institute of Technology is working on developing a structural battery that uses a battery with strength as part of the vehicle body to reduce the battery load to almost zero.

The idea of using the battery as part of the body has existed. For example, Italian automakers Lamborghini and MIT Tech announced Terzo Millennio, an electric vehicle concept model that achieves lighter weight and space savings by embedding a battery in the wheel in 2017.

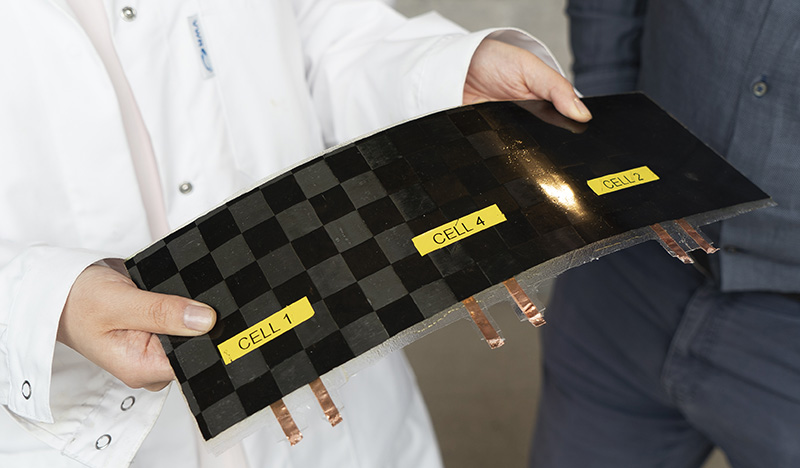

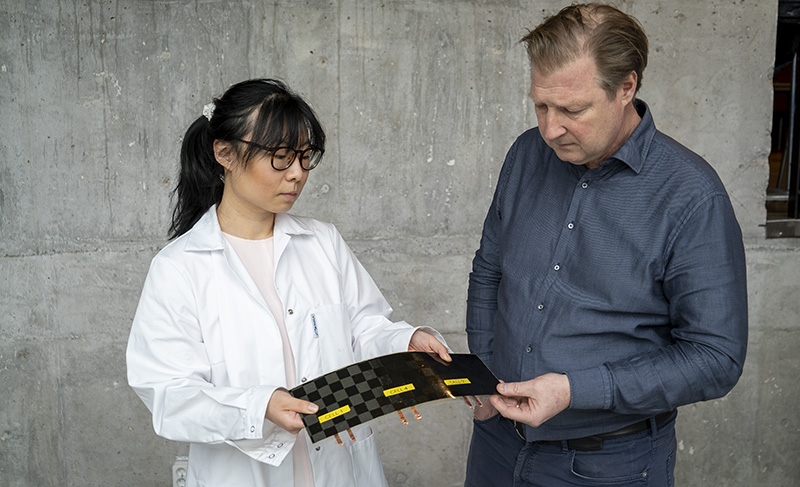

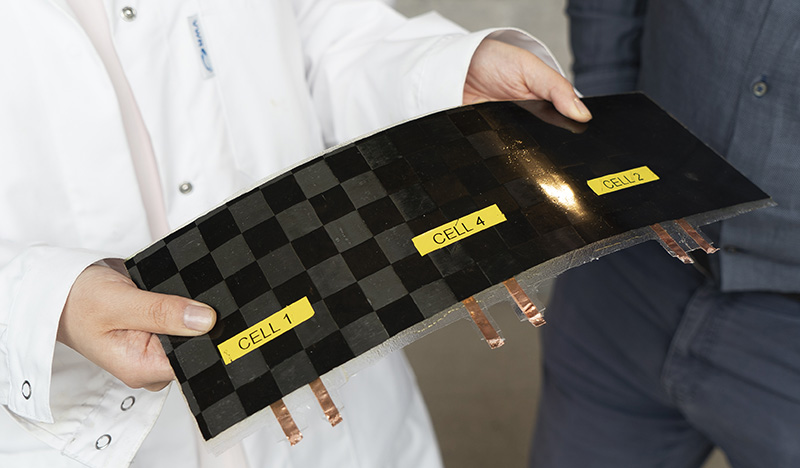

In the practical use of such structural batteries, it is necessary to solve the problem of balancing strength and battery performance. The research team noted that carbon fibers used in carbon fiber reinforced carbon composite materials will function as a battery negative electrode. In collaboration with the Swedish Royal University of Technology research team, it developed a carbon fiber structural battery capable of storing electric energy while maintaining high strength and rigidity.

This battery was manufactured by combining a carbon fiber electrode and a lithium iron phosphate electrode with a cloth made of glass fiber and adding an electrolyte to it. This structural battery energy density is 24Wh/kg, and the capacity per weight is said to be about 20% of the current lithium-ion battery. On the other hand, the research team said that using such a structural battery can significantly reduce the weight of the vehicle, thereby reducing the electric energy required to run an electric vehicle, and its stiffness is 25 GPa, which is comparable to that of general building materials. In addition, it is explained that it can be said that it is rather advantageous in terms of safety due to its low energy density.

In addition, structural batteries made so far are only excellent among mechanical properties or electrical properties, that is, strength or size, but it is revealed that they have succeeded in designing competitive structural batteries in all of them by employing carbon fiber.

The research team plans to further improve this structural battery through a new project funded by the Swedish National Space Commission. In this way, it is expected to realize a structural battery with 75Wh/kg energy density and 75GPa stiffness comparable to aluminum. Related information can be found here.

Add comment