Human muscles are strong, soft, contain a lot of moisture, and are resistant to fatigue. However, according to a new study by MIT, it has found a method to reproduce these muscle-like properties with synthetic hydrogel materials.

The research team announced that the gel material was mechanically repeatedly stretched and stretched in water to gain flexibility and resistance to damage and fatigue. To put it simply, it means that I became strong through muscle training like a muscle.

This gel material is called polyvinyl alcohol hydrogel PVA-H. The mechanical strength can be varied in various ways depending on parameters such as polymerization degree, saponification degree, and concentration of PVA (polyvinyl alcohol). In addition, the state in which water has penetrated is used in a blood vessel model or oral model close to a living body, and is also used for medical implants. MIT says about PVA-H that most of the human tissue contains 70% moisture, so it is desirable that the material for implantation in the body also has a high moisture content.

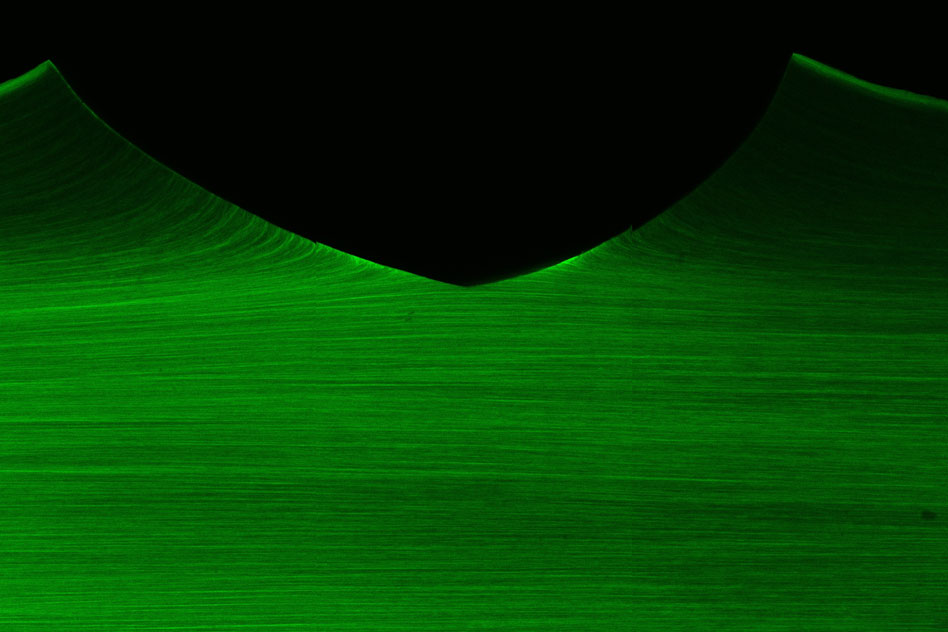

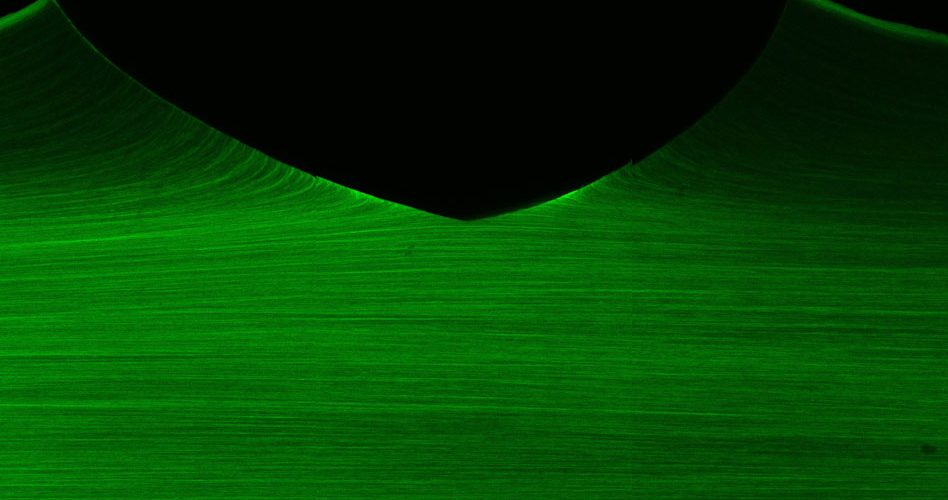

Before muscle training, the fibers in the material were in a random orientation. However, when you start stretching, the fibers gradually align. It is said that it is strong but soft and durable as a result of repeated stretching 1,000 times. Numerically, it achieved 4.3 times more tensile strength than the sagging state without any muscle training.

Until now, it was possible to make a hydrogel in which fibers were aligned in the same direction to provide strength from the beginning. However, it is said that in most cases there is no flexibility such as muscle or there is no water content necessary for the living body.

Originally, it was a study started to find the fatigue point at which hydrogel begins to collapse through mechanical load, but the result was the discovery that the hydrogel is strengthened as if it were muscle training. In this experiment, they did 1,000 stretching exercises, but some of the materials were said to have endured up to 30,000 times. Even after training, the material showed flexibility and maintained a high moisture content of 84%.

The research team hopes that one day, these properties can be used in engineering applications such as implants or soft robots in heart valves, artificial cartilage, and spinal discs. Unfortunately, the gel material itself doesn’t become a muscle when put in the body. Related information can be found here .

Add comment