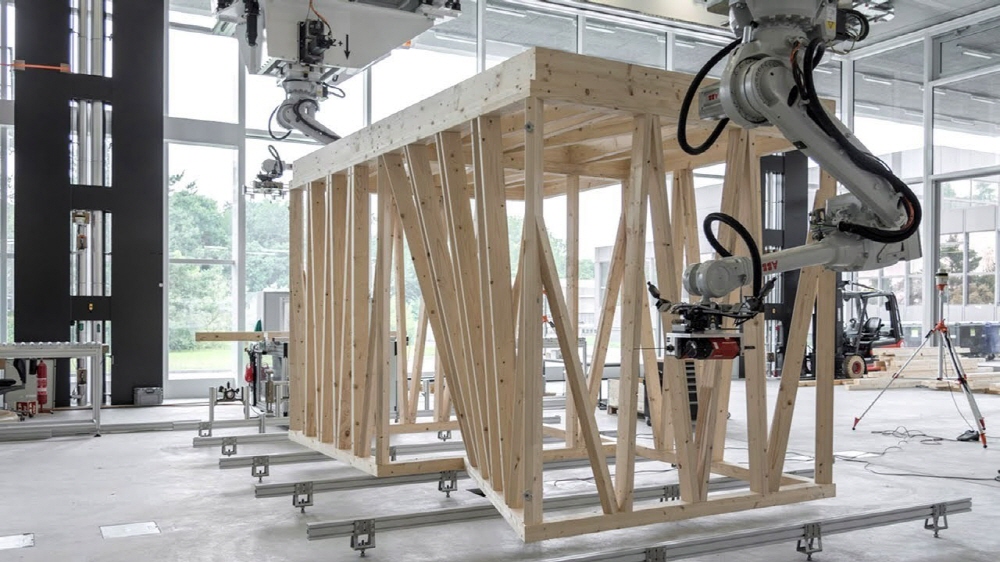

The Zurich Institute of Technology and the Swiss floating company Erne AG Holzbau are working together on a technology to assemble buildings using industrial robotic arms. Numerous robotic arms carry trees and cut tools to assemble building frames.

According to a research team at the University of Zurich, the method is called Spatial Timber Assemblies and will expand design possibilities. All processes, such as cutting trees, are assembled with the hands of a robot. This method is a complex construction, such as the algorithm calculating the strength, but it has the advantage that the robot can assemble the design on its own, even if it is installed at different angles per column or requires human intervention. Humans can finally fix the frame by screwing the tree into it. Even at this time, the computer does not need to use unnecessary reinforcement plates through precise calculations, so it can be made with minimal materials.

Plans to build prefabricated houses as modules using this method have already been prepared. When incorporating a module that can build a two-story house has a floor space of over 100m 2. The robotic arm is suspended from a crane in the factory, so it cannot work on a construction site. However, you can expect the advantage as it can efficiently construct complex designs with minimal materials. Related information can be found here .

Add comment