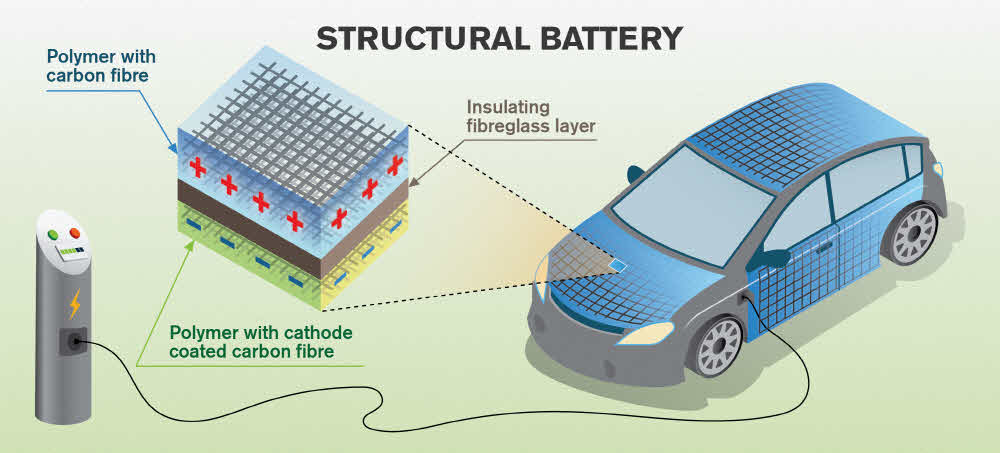

A research team from Sweden’s Chalmers Institute of Technology has published a study showing that carbon fibers can be used for battery electrodes as well as for high strength materials. Interestingly, for example, the possibility of using carbon fiber in an electric car or aircraft body as well as a battery is suggested.

Electric cars need a large capacity battery to extend their range, ie, to increase the mileage continuously. The problem is that the mounting space is limited and the batteries are full, and the weight is also a problem. The researchers say the bodywork will be able to operate on batteries as well as simple structural functions.

To battery the carbon material used in the car body, it is necessary to optimize the carbon fiber size and structure and to improve the balance between the electrochemical properties and stiffness required for energy storage. The researchers studied the microstructure of a variety of carbon fibers that are not yet commercially available, and found that carbon fiber materials with low crystals and poor orientation have a somewhat lower stiffness but good electrical properties.

The research team, however, does not seem to be a problem for use in automobiles, even if the stiffness is reduced a little. However, since carbon fiber composites that are high in stiffness and expensive are used for aircraft, Can be expected. Using carbon fiber as a conductor instead of sensors and cables that sense kinetic energy can reduce vehicle weight by up to 50 percent, he added.

However, carbon fiber itself has a drawback that it is expensive. It is well used in racing cars and high-tech industries, but it is a situation that gives priority to function and performance over cost. The results of this research show that it is necessary to drastically lower the manufacturing cost of the carbon fiber material itself before it can be practically used in electric vehicles. For more information, please click here .

Add comment