Kristiansand in the south of Norway and Trondheim, the center of the central region, are linked by the road E39. This road is located on the west coast of Norway, where a fiord called fjord is intertwined, so you have to use the ferry in eight parts. Because of that, the speed and the satisfaction were inevitably lowered remarkably.

In order to solve this problem, the largest road construction project will be conducted to allow the fiords to pass through tunnels and bridges. Once completed, the world’s largest tunnel will also be located here.

As I mentioned earlier, there are many fjords in the western part of Norway that are deep fjords created by glacier erosion. The E39 is a road that runs 1,100 km on the west coast. The problem is that it takes 21 hours to get the full distance because of the help of the ferry at eight locations. The road construction project is to build bridges and tunnels across the fjords where ferries must be used.

In the southern part of the fiord, an undersea tunnel of 27 kilometers in length and 390 meters in depth is made. If completed, it will be recorded as the largest and deepest underwater tunnel in the world. Two lanes are constructed in parallel with each other, and both tunnels are connected by a passage. In the middle, shelters and emergency escape routes are also provided. There will also be an entrance to the island located in the middle.

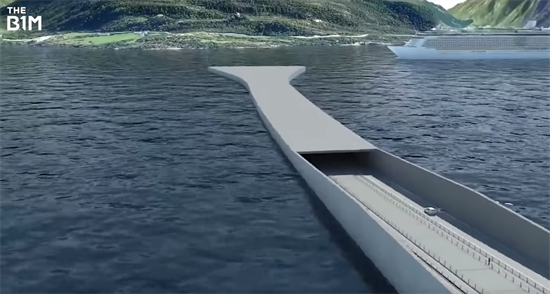

It will also build a 5km-long bridge in the fiord, 600m deep inside. He says he is considering one of the suspension bridges and floating underwater tunnels where 400m deep and 4km wide construction is needed. Underwater floating tunnels can be tunnels in the form of a bridge across the fiord. As for the tunnel type, two lanes are constructed for each line. Taking this approach will result in a tube-shaped tunnel that floats in the fiord, rather than an undersea rock.

Sogne Fjord is the place where the biggest challenges are expected. It is the longest fjord in Norway with a length of 204 km, deeply digging into the shoreline of the coast. As long as 204km, it is almost impossible to make an underwater tunnel because the depth is 1,308m. In addition, it is necessary to secure 400m wide, 70m above the water surface and 20m below the water surface for a large ship to sail.

One of the things considered for this reason is suspension bridges. Of course, unlike ordinary suspension bridges, it is a kind of subtype bridge that has built a pylon fixed to the fiord with an anchor. The sunne fjord is deep and the main tower is built on the footboard connecting the two sides, so that the main tower can not be directly anchored down to the sea floor. That’s a lot of engineering challenges.

Of course, there is also a way to make it an underwater floating tunnel besides this method. However, in this case, the whole of the fiord is not passed through the tunnel, but only part of the route is partially tunneled. The plan is expected to be a new model for infrastructure projects around the world, if both safety and environmental considerations are needed.

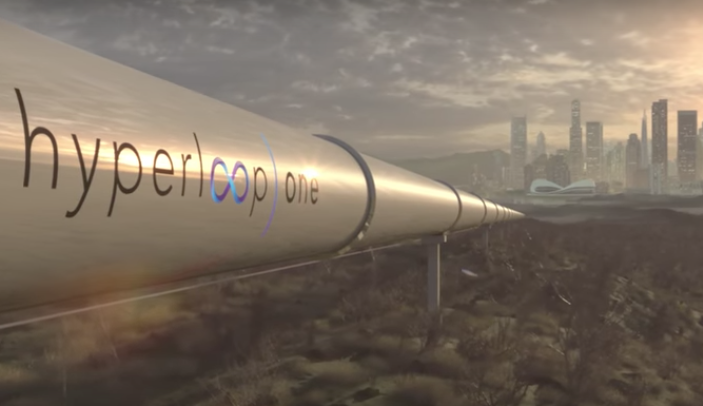

Construction has long been a part of mankind, but it is a past, present and future power. There is a project to connect arteries, as in Norway, but future projects like Hyperloop, a subsonic transit system proposed by Tesla founder Elon Musk, make this future a dream.

The hyper-loop is, in short, a vacuum train running in a vacuum, which theoretically can run at speeds up to 1,200 km / h. HTT (Hyperloop Transportation Technologies), one of the companies trying to implement it, said it started construction of experimental tubes in France this year. It is the third hyper-loop tube in the world, and it is also the first to be built in Europe.

As mentioned above, the hyper loop is a next-generation transportation system in which a train carrying a person or a load in a tube depressurizing the air travels at supersonic speeds of 1,200 km / h using electromagnetic force. The tube to be built in France is going to be in two stages, and it is planned to construct a 320m course this year and complete the 1km long facility in 2019. The car to run inside is being produced in Spain and will be completed this year.

HTT, as well as another company that is promoting the HyperLoop, Hyperloop One, built a test facility near Las Vegas and ran a 310km / h driving test in 2017. As well as the HyperLoop circle, HTT is also stepping closer to realizing the hyper-loop while building facilities in France.

https://youtu.be/uLh1alyhc1E

Elon Musk, who proposed the hyper-loop project, is trying to build an underground high-speed traffic system in the United States. The Boring Company, a privately owned tunnel excavator company, is actually conducting a project to mitigate traffic congestion by selling underground tunnels to Los Angeles.

In addition, the Boring Company said it had received bids for the construction of an underground highway traffic system from the Chicago airport to the city in June. It wants to build an underground highway traffic system from Chicago O’Hare International Airport to downtown block 37, which is the center of Chicago downtown. It took about 30 to 40 minutes to travel 24 kilometers by means of a railway or taxi, but it would take 12 minutes to build an underground highway traffic system. It is not yet possible to calculate the exact fare, but it will be higher than the $ 5 when connected by rail, but lower than the $ 40 taxi fare.

The vehicles used in the underground high-speed traffic system are Tesla’s Model X-based electric cars. The maximum speed is 240 km / h. There are 8 to 16 seats in the vehicle, with air conditioning, luggage storage and Wi-Fi. The vehicle will run 20 hours a day at 30-second intervals.

https://youtu.be/tfV8z2JY_bI

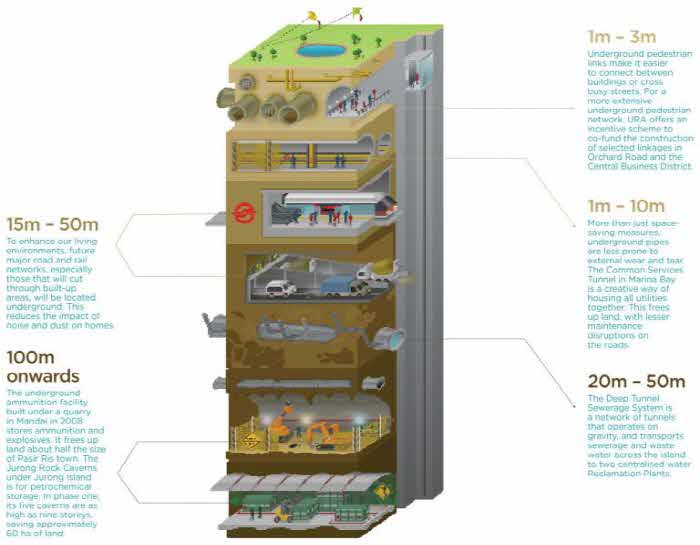

In addition to transportation, there are places where underground city planning is set up to increase utilization of limited land mass. In the case of Singapore, the country is only 619.1 km2. However, the population is 5.6 million, the second highest in the world after Monaco. To promote the limited utilization of the land, we are going to develop underground space.

Singapore has built a warehouse where subway, car tunnels, sewage treatment facilities and ammunition can be placed in underground pipelines, where pipelines can be laid in the underground, such as walking trails, wires and communications lines. In the case of the Common Service Tunnel located in the Marina Bay area, it is equipped with a power network, a communication network and a water supply facility in a 3km-long tunnel. The tunnel is equipped with a facility (District Cooling Plant) that can be used for cooling and heating ground water by circulating cold water.

In the case of an ammunition made by digging a rock around 100m underground, it is possible to reduce the area by 90% compared to making ammunition on the ground by utilizing the quarry in the past, and it is possible to use the land of 400 soccer fields elsewhere do. Singapore has also built a Jurong Rock Caverns (JRC), an oil storage facility, in the 130-meter underground man-made island south-west of the main island. It stores raw oil or naphtha. It is an essential facility for the petrochemical industry in Singapore, so it has a high security system.

The JRC is the first underground storage facility in Southeast Asia that has been planned since the 1980s with the rapid growth of the Singapore economy. Five caves in the basement are 340 m long, 20 m wide, and 27 m high, 9 stories high. The entire scale is able to store up to 64 swimming pools and 1,300 second-floor buses. However, the Singapore government says it is under construction to double the capacity of JRC.

The Singapore government is undergoing the Land and Liveability National Innovation Challenge. The project aims to provide cost-effective and space-optimized space for Singapore’s long-term development. In addition to industrial fields, they are also planning to construct facilities such as underground stadiums and libraries.

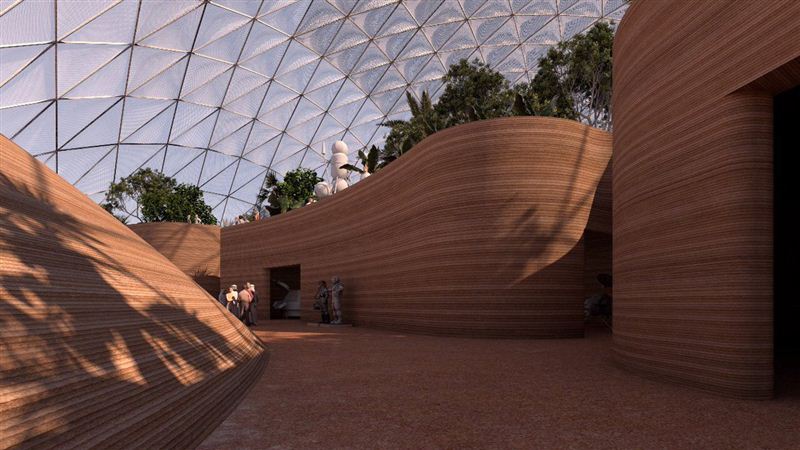

Construction is also used to simulate future space exploration. Dubai also announced plans to build a city in the desert that simulates Mars’ living space named Mars Science City Project last year. And to build an artificial city that can conduct research on Mars migration in the desert near Dubai. It creates a facility to reproduce the Mars environment in a total area of 190,000 square feet. Dome-shaped houses actually make facilities for people to live on, and they work on agricultural cultivation and energy and water circulation systems in rough land.

Inside the accommodation, museums to exhibit space development achievements will be introduced and related education facilities will be created. The building will use the sand in the desert as a material and output it to a 3D printer. The budget is expected to be $ 150 million. Of course, there is no specific schedule yet.

Dubai has said it will use the 3D printer output, but it is also attempting to print houses for developing countries. Dreaming of building construction innovation through technology called 3D printer. It is a fact that the population of 1.2 billion people in the world can not have stable housing yet.

![]()

The startup icon (ICON) says that a 3D printer can be used to build a house for $ 10,000. Icon CEO Jason Ballard says a 3D printer house is much cheaper than a typical American home and will make it easier to build homes in areas where economic support is needed.

According to the icon, it takes 12 to 24 hours to construct a 60m2 cement house that can be output to a 3D printer. It has a living room, a bedroom, and a bathroom, and is structurally robust because it uses cement.

Icahl is testing plans to build a home in a 24-hour 3D printer, in partnership with Newsley, an organization that supports housing issues in Haiti, El Salvador and Bolivia. If it goes smoothly, it will be possible to create 100 houses made of 3D printers by 2019 in places like El Salvador.

In the Netherlands, there is also a hemispherical housing that can be found in SF movies in the southern city of Siergarten. This hemispherical house, which is rounded with cement and glass fiber on the outer wall, was already built in 1984. It has 11 circular windows designed to receive a lot of external light. The interior is divided into 3 floors, the first floor is a bedroom, the second floor is a bathroom, and the third floor is a living space.

This attempt was a creative approach to environmental improvement and new initiatives, but in Eindhoven, the Netherlands, recently, a plan to build homes built with 3D printers that could actually be inhabited attracted attention.

The City of Eindhoven, the city council, the Eindhoven Institute of Technology, and the construction company jointly announced the plan. Although 3D printers will comply with architectural standards, they can easily make shapes that are difficult to use by taking advantage of 3D printers. There is an advantage that less unnecessary materials are used because only a minimum amount of material is used. It is said that the city will have a unique shape with five houses to be built. It will be a residential type that makes full use of the features of 3D printers that can be freely constructed.

If it is scheduled, we will make one in the middle of next year. The first house will be a one-story house with three bedrooms. After that, we will make 5 units over the next 5 years. The development of housing technology using 3D printers will give people with brick or related technology skills, but houses built with 3D printers may be a solution to this decline. The construction combined with this technique is making a glimpse of the present as well as the future.

Add comment